of

BLESSED VIRGIN MARY

Chapel

then do what's possible; and

suddenly you are doing the impossible.

- St. Francis of Assisi

Inspection & Mitigation

Exterior Masonry & Conditions Report

Recommendations – Phase II

Recommendations – Phase III - Future Work

Inspection & Mitigation

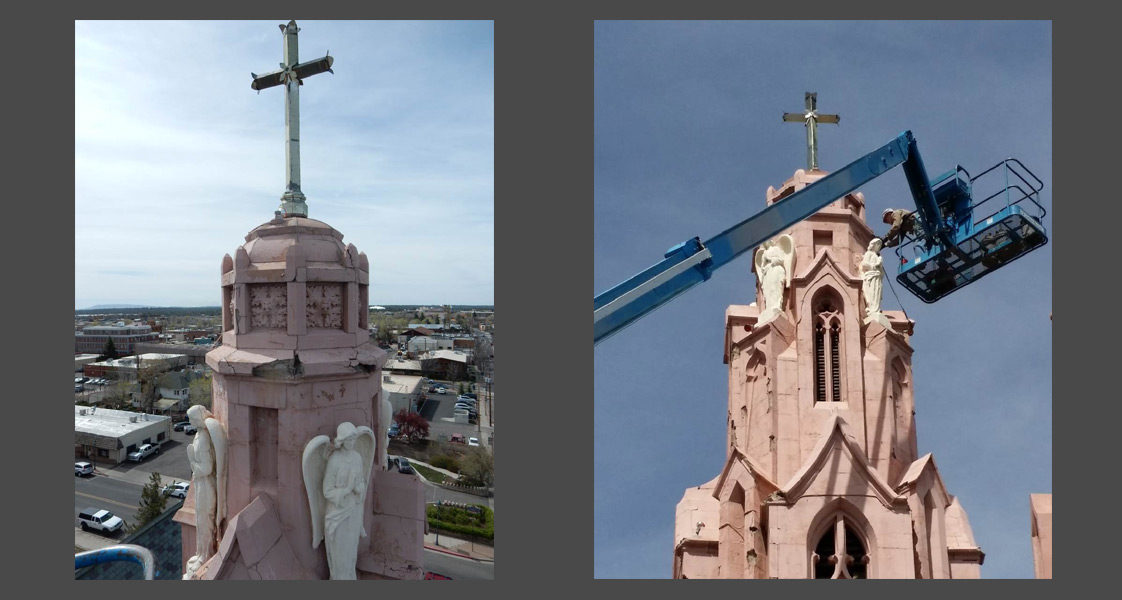

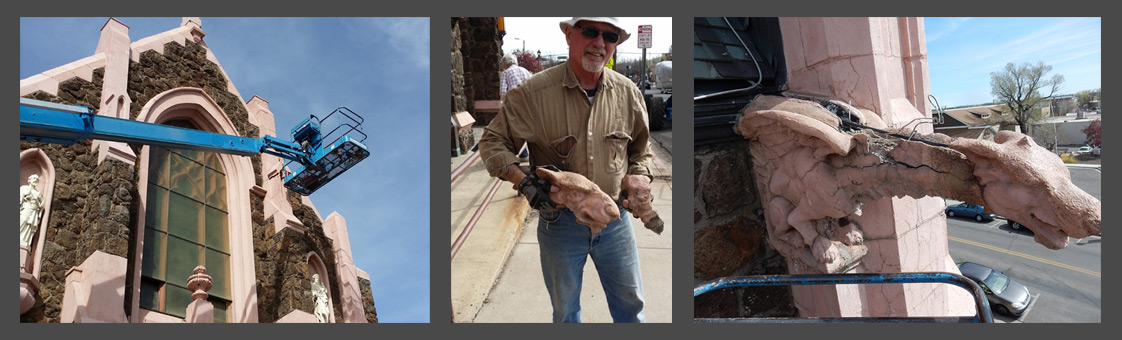

In April 2015, initial inspection and hazard mitigation of the exterior decorative concrete and stonework was performed by historical masonry expert Charles Kibby of CGI Preservation, Los Angeles. The resulting Exterior Masonry & Conditions Report quoted below summarizes his findings.

Exterior Masonry & Conditions Report

“The Chapel is constructed of cast-in-place structural concrete clad in a decorative veneer of local lava stone combined with decorative cast stone trim... the bell tower is much more extensively detailed with Gothic style trim in decorative cast stone.”

“The most striking fact of our initial observation was the general surface deterioration at the cast stone areas of the structure, particularly on the bell tower. There were widespread occurrences of this deterioration wherever previous application of an elastomeric coating had taken place. “

“Closer examination... showed the decorative cast stone portion of the façade had, over time, undergone multiple applications of repair mortars and coatings, indication of a long-standing problem with the stability of the substrate... The most recent iteration of coating was but the latest in a probable series of attempts to stabilize the cast stone façade material.”

“These various coatings have trapped moisture... During freeze-thaw conditions this interior moisture freezes, expands, and breaks down the Portland cement matrix of the original decorative cast stone... causing the loss of inner substrate material.”

“The extent of moisture penetration through the veneer as well as the inner concrete can be seen in the efflorescence present on the interior of the tower structure.”

Some areas were extremely friable, while others came off in large pieces. Well-intentioned application of elastomeric paint many years ago created a rubberized barrier that trapped moisture, likely worsening deterioration of the decorative concrete.

Iron jacking, or oxide jacking, caused by the expansive force of rusting iron reinforcing bars within the concrete, has fractured exterior statues and the decorative pinnacle above the main entrance.

“The decorative gargoyle figures on the east and west elevations have suffered particularly extensive failure due to internal reinforcing steel decay, with substantial loss at more than half of the figures.” During the survey, one loose gargoyle was removed, as was the large, lower right buttress pinnacle on the south elevation.

“Based upon our initial review of the façade, it is anticipated that up to 50% of the cast stone units have been damaged beyond restoration, and should be replaced with new matching cast stone units.”

“The lava stone portion of the veneer, by far the greater in terms of area, is in very good shape, due to its inherent material properties. Portland cement grout in the joints between stones was found to be in relatively good shape, with only a few locations needing re-pointing.”

“Leaded glass windows and slate roofing are two areas needing further investigation by specialists in these areas. The slate roof was observed to be missing a few tiles and offered moisture intrusion paths at several of these locations.” The roof is made of imported Belgian slate.

The original decorative masonry was the reddish earth tone of local cinder hills.

Recommendations: Phase II

After removal of loose debris in April 2015, it was recommended elastomeric paint be applied to newly exposed areas of concrete as a temporary measure to prevent excessive water penetration of the structure.

It was also recommended rubber molds be made of the left and right-facing gargoyles for later reproduction, as the gargoyles were not likely to survive another winter.

(In August 2015 during Phase II of the restoration, winterization of the exposed concrete was completed, gargoyle molds were made, and the stained glass windows were inspected.)

Recommendations: Phase III - Future Work

Due to architectural and restoration complexities, it has been recommended that a structural and material engineering firm with expertise in slate roofs and historical masonry be consulted for the following:

- an analysis of the chemical composition and compression strength of the concrete to determine whether and how the existing masonry can best be preserved

- a recommendation of restoration methods and materials most cost effective that would help avoid future problems

- an analysis of remaining building envelope, i.e. slate roof, chimney, and window and door openings

- construction drawings to complete the restoration and a prioritized schedule of work

READ MORE: Phase II – August 2015 – Gargoyle Molds & Window Inspection

~ Ave Maria ~